Component Board Level Test

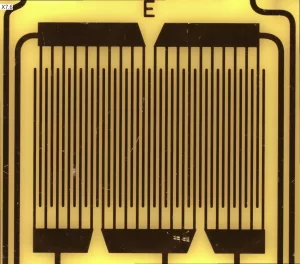

According to IPC/JEDEC-9703, component-level board testing refers to conducting various tests on a single type of component using a simplified test board. During the design of the test board, a daisy chain is used to monitor the quality of solder joints. The reliability testing items include:

Board Level Thermal Cycling Test

This assesses the thermal fatigue life of solder joint materials, components, or circuit boards under thermal stress due to thermal fatigue effects. The general failure criterion, as per IPC-9701, is defined as a 20% increase in electrical resistance observed in five consecutive readings, which is considered a failure. Failure modes can be analyzed through cross-section observation or dye-and-pry testing.

Board Level Drop Test

This evaluates the drop life of electronic products under mechanical shock effects in a drop acceleration environment. As per the JESD22-B111 standard, the component side is mounted facing down on the base of the test apparatus and then tested under specified conditions. These conditions include maximum impact acceleration, impact duration, and change in velocity. The standard defines failure as when resistance is detected to be over 100 ohms or increases by 20%, and this outcome is repeated in three out of the next five readings.

Environmental Stress Test

Due to the diversity of environments in which electronic products are used, conducting reliability assessments under various environmental conditions has become essential. Common influencing factors include temperature, humidity, and external forces. Equipment can simulate the effects of these factors and accelerate the evaluation process to confirm the product’s performance under extreme conditions.

Cheetah Inspection Inc. can provide the following Environmental Stress Tests:

- Thermal Storage Test: Evaluates the stability of products when stored at specific temperatures.

- Temperature/Humidity Storage Test: Assesses the effects of both temperature and humidity on products over a storage period.

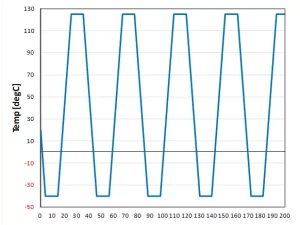

- Thermal Cycling Test: Tests the product’s ability to withstand changes in temperature over a range of cycles.

- Thermal Shock Test: Determines the product’s tolerance to rapid temperature changes between two extreme temperatures.

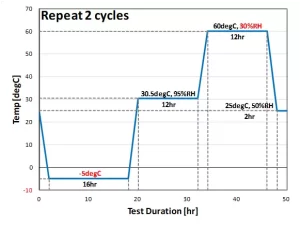

- Temperature/Humidity Cycling Test: Simulates conditions where both temperature and humidity vary cyclically, testing the product’s resilience.

- Highly Accelerated Stress Test (HAST): Accelerates the aging process of the product using high temperature and humidity to identify potential failures.

- Mechanical Shock Test: Assesses the product’s capacity to withstand mechanical shocks or impacts.

- Bending Test: Evaluates the product’s flexibility and resistance to bending forces.

SIR, Surface Insulation Resistance

As the spacing between circuit lines decreases and the density of soldering increases, the residue of flux on the surface of circuit boards can affect the reliability of electronic products. Cheetah Inspection Inc. assists clients in evaluating whether short circuits might occur between two lines under varying line widths and spacings. During testing, samples are placed in an environment with controlled temperature and humidity, and a specific voltage is applied. The changes in the insulation resistance between the lines are then observed to assess the risk of short circuits.

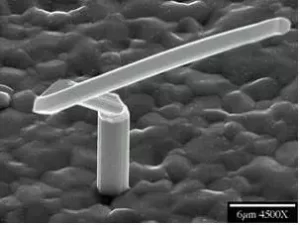

Tin Whisker Test

The primary cause of tin whisker formation in electronic components is the residual stress left in the tin plating, leading to the protrusion of tin crystals. Alternatively, it can be due to the protrusion of tin crystals under long-term temperature stress in solder materials. Generally, the growth rate of tin whiskers is quite slow, and their length is limited. However, under certain conditions (such as stress and temperature), tin whiskers can grow more rapidly. If they grow too long, they increase the risk of short circuits in electronic components.

Tin whisker testing includes:

Reliability Test (Temperature Cycle Test, Temperature/Humidity Storage Test)

JESD201 outlines the environmental requirements for tin and tin alloy surface treatments on various components, defining the acceptable levels and grades of tin whiskers after different environmental stress tests, such as thermal cycling and temperature/humidity storage.

Scanning Electron Microscope (SEM)

JESD22A121 specifies the method for measuring tin whiskers. Due to their small size (micrometer level), tin whiskers must be captured and measured using an electron microscope.